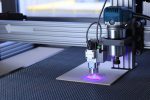

Is Laser Cutting The Same as Laser Engraving?

blogpost

In the realm of manufacturing and craftsmanship, laser technology has revolutionised the way we create intricate designs and precise cuts. Two commonly used processes, laser cutting and laser engraving, are often mentioned interchangeably, leading to confusion among enthusiasts and professionals alike. In this blog post, we'll unravel the distinction between laser cutting and laser engraving.

Distinguishing Between Laser Cutting and Laser Engraving

Both laser cutting and laser engraving harness the power of focused laser beams to modify materials, but they serve distinct purposes and employ different techniques.

Key Points:

- Laser Cutting: Laser cutting involves using a high-powered laser beam to slice through materials, creating precise cuts along predefined paths. This process is ideal for cutting intricate shapes and designs from various materials, including wood, acrylic, metal, and fabric. Laser cutting is commonly used in industries such as manufacturing, prototyping, and crafting to produce custom parts, signage, and decorative elements.

- Laser Engraving: Laser engraving, on the other hand, entails using a laser beam to remove surface material from a substrate, leaving behind a permanent mark or design. This process is commonly used to add detailed graphics, text, or patterns to a wide range of materials, including wood, glass, metal, and plastic. Laser engraving is prized for its precision and versatility, making it popular in industries such as signage, personalization, and branding.

Insights from Laser Experts

To gain authoritative insights into laser cutting and laser engraving, we turn to experts who possess extensive knowledge and experience in the field.

Dr. Emily Chen, a materials engineer specialising in laser technology, shares: "Laser cutting and laser engraving are distinct processes that offer unique capabilities and applications. While laser cutting excels at creating precise cuts with minimal material waste, laser engraving enables intricate surface decoration and customisation."

John Davis, a laser technician with years of experience in laser systems, comments: "Understanding the differences between laser cutting and laser engraving is essential for selecting the appropriate process for specific applications. Both techniques offer unparalleled precision and efficiency, but they serve different purposes and require tailored parameters for optimal results."

Clarifying the Distinction Between Laser Cutting and Laser Engraving

In conclusion, while laser cutting and laser engraving both leverage laser technology to modify materials, they serve distinct purposes and offer unique capabilities. Laser cutting excels at creating precise cuts and shapes, while laser engraving enables detailed surface decoration and customization. By understanding the differences between these processes and their respective applications, enthusiasts, professionals, and businesses can harness the power of laser technology to bring their creative visions to life with precision and efficiency. So, the next time you embark on a laser project, remember to choose the right technique for the job and unleash the full potential of laser cutting and laser engraving.

Beyond the Basics: Advanced Moulding Techniques for Acrylic Sheets

blogpost

Acrylic sheets, known for their clarity and versatility, are a popular choice for various applications. While basic techniques like bending and glueing can achieve simple shapes, complex designs demand venturing into advanced moulding methods. This blog post delves into techniques that push the boundaries of what's possible with acrylic, allowing you to create unique and functional pieces.

1. Heat Bending:

This method utilises heat to soften the acrylic sheet, making it pliable for shaping around a mould.

Techniques:

- Strip Heater: A focused heat source like a strip heater allows for precise control over the bend area.

- Oven Bending: For larger bends, acrylic can be heated in a temperature-controlled oven, followed by quick-forming around a mould.

2. Vacuum Forming:

This technique involves applying heat and a vacuum to form the acrylic sheet over a mould cavity.

Process:

- The acrylic sheet is heated until pliable.

- A vacuum is applied, forcing the softened sheet to conform to the mold's shape.

- The acrylic cools and retains the moulded form.

3. Pressure Forming:

Similar to vacuum forming, pressure forming utilises compressed air to push the heated acrylic sheet onto a mould. This technique is suitable for deeper and more complex shapes.

4. Chemical Bending:

This method involves applying a solvent along a designated scoreline on the acrylic sheet. The solvent weakens the material, allowing it to be bent along the scoreline.

- Important Note: Chemical bending requires specific solvents compatible with acrylic and should only be attempted with proper safety measures and ventilation.

5. CNC Machining:

Computer Numerical Control (CNC) machining utilises computer-controlled tools to precisely cut and shape acrylic sheets. This method offers exceptional precision for intricate designs and lettering.

Beyond the Technique:

- Polishing: After moulding, polishing removes surface imperfections and enhances the acrylic's optical clarity.

- Bonding: Acrylic pieces can be securely bonded using specialized adhesives to create complex structures.

Safety First:

Always prioritise safety when working with acrylic. Utilise proper ventilation, wear necessary personal protective equipment, and thoroughly research each technique before attempting it.

Conclusion:

Mastering these advanced moulding techniques opens a world of possibilities for working with acrylic sheets. From creating unique art pieces to fabricating functional objects, these methods allow you to translate your vision into reality. Remember, with practice and knowledge, you can push the boundaries of what's achievable with this versatile material.

How is Perspex Manufactured?

blogpost

Perspex, a brand name for acrylic sheet, is a versatile and popular material used in various applications, from construction and signage to furniture and even medical devices. But have you ever wondered how this transparent wonder comes to life? While we may not manufacture Perspex ourselves, we are a leading supplier and fabricator of the material, and by delving into the broader Perspex manufacturing process, we can shed light on this fascinating journey.

The Birth of a Sheet:

- Raw Materials: The story begins with a combination of liquid monomers, the building blocks of Perspex. These monomers, primarily methyl methacrylate (MMA), are carefully chosen and measured to achieve the desired properties like clarity, strength, and thickness.

- Polymerisation: The magic happens in a process called polymerisation. The liquid monomers are heated and stirred under controlled conditions, causing them to link together and form long chains, essentially creating the plastic structure of Perspex.

- Casting or Extrusion: Depending on the desired thickness and application, Perspex can be formed through two primary methods:

Casting: Molten Perspex is poured into molds of the desired shape and thickness. Once cooled and solidified, the Perspex sheet is removed from the mold. This method is suitable for thicker sheets and allows for the incorporation of pigments or additives for coloured or specialised Perspex.

Extrusion: For thinner sheets, molten Perspex is forced through a die of the desired shape, similar to how toothpaste is extruded from a tube. This method is faster and more efficient for producing large quantities of thinner Perspex sheets.

The Finishing Touches: After formation, the Perspex sheets undergo various finishing processes, including:

- Cooling: The newly formed sheets are carefully cooled to ensure proper solidification and prevent warping.

- Annealing: This process involves controlled heating and cooling to relieve internal stresses within the material, improving its strength and optical clarity.

- Surface Finishing: Depending on the intended use, the Perspex sheet may be polished, textured, or coated with additional layers for specific functionalities.

From Molten Liquid to Versatile Material:

The journey of Perspex from raw materials to the finished sheet is a testament to modern material science and engineering. Understanding this process allows us to appreciate the intricate steps involved in creating this widely used and versatile material that plays a significant role in our daily lives.

Remember, while here at Dennyplastics.co.uk we may not manufacture Perspex, we are experts in supplying and fabricating it into various shapes and applications. Make sure to take a look around our website to learn more about our services and explore the endless possibilities of Perspex!

Bespoke Fabrication: Tailoring Solutions for Commercial Spaces

blogpost

In the dynamic landscape of commercial design, the concept of bespoke fabrication emerges as a beacon of innovation and customization. As businesses strive to differentiate themselves and create unique brand identities, the demand for tailor-made solutions in commercial spaces has surged. From retail establishments to corporate offices, bespoke fabrication offers a versatile toolkit for architects, designers, and business owners alike to craft spaces that resonate with their vision and purpose.

The Essence of Bespoke Fabrication

Bespoke fabrication transcends the limitations of off-the-shelf solutions, offering a bespoke approach tailored to the specific needs and aspirations of each project. At its core, bespoke fabrication embodies the art of customisation, where form meets function in a seamless fusion of design and craftsmanship.

In the realm of commercial spaces, the requirements are as diverse as the businesses they house. Whether it's a flagship store seeking to create an immersive brand experience or a collaborative workspace aiming to foster creativity and productivity, bespoke fabrication provides the flexibility to realise ambitious design concepts while addressing practical considerations.

Tailored Solutions, Endless Possibilities

One of the key advantages of bespoke fabrication lies in its ability to accommodate a wide array of materials, techniques, and design preferences. From wood and metal to glass and composite materials, the palette of possibilities is virtually limitless. This versatility enables designers to experiment with textures, finishes, and structural elements, thereby creating spaces that are both visually striking and functionally robust.

Moreover, bespoke fabrication allows for the integration of advanced technologies such as CNC machining, laser cutting, and 3D printing, enabling the realisation of intricate patterns, complex geometries, and interactive installations. Whether it's a custom-built display unit, a sculptural centrepiece, or a kinetic façade, the only limit is the imagination.

Elevating the customer experience

In today's competitive business landscape, the customer experience reigns supreme. From the moment a patron sets foot inside a retail store or steps into a hotel lobby, every interaction shapes their perception of the brand. Bespoke fabrication offers a powerful means to curate memorable experiences that resonate with customers on a visceral level.

By infusing elements of craftsmanship and artistry into the built environment, bespoke fabrication elevates the customer experience from mundane to extraordinary. From handcrafted fixtures and bespoke furniture to immersive multimedia installations, every detail serves as a testament to the brand's commitment to excellence and innovation.

The Future of Commercial Design

As we look to the future, the role of bespoke fabrication in commercial design is poised to expand even further. With advancements in digital fabrication, sustainable materials, and parametric design, the possibilities for innovation are boundless. From sustainable architectural solutions to interactive retail environments, bespoke fabrication will continue to shape the way we experience and interact with commercial spaces. In conclusion, bespoke fabrication represents a paradigm shift in the way we conceive, design, and inhabit commercial spaces. By offering tailor-made solutions that marry form and function, bespoke fabrication empowers businesses to create environments that inspire, engage, and delight. As the boundaries of design continue to blur, bespoke fabrication stands as a testament to the enduring power of creativity and craftsmanship in shaping the world around us.

Behind the Scenes: The Process of Plastic Fabrication Revealed

blogpost

Plastic fabrication is an intricate process that involves transforming raw plastic materials into a wide range of finished products used in various industries, from automotive and aerospace to medical and consumer goods. In this blog post, we will delve into the fascinating world of plastic fabrication, exploring the key steps and techniques involved in bringing plastic products to life.

1. Design and Planning

The plastic fabrication process begins with meticulous design and planning. Engineers and designers work closely to conceptualise the product, considering factors such as functionality, aesthetics, and manufacturing feasibility. Advanced design software allows for precise modelling and prototyping, enabling stakeholders to visualise the final product before fabrication begins.

2. Material Selection

Choosing the right plastic material is crucial to the success of the fabrication process. There are numerous types of plastics available, each with its own unique properties and characteristics. Factors such as strength, durability, flexibility, and temperature resistance play a significant role in determining the most suitable material for the intended application. Common types of plastics used in fabrication include acrylic, polycarbonate, polyethylene, and PVC.

3. Cutting and Shaping

Once the design and material selection are finalised, the fabrication process moves to cutting and shaping the raw plastic materials. Advanced cutting techniques such as laser cutting, CNC routing, and water jet cutting allow for precise shaping and sizing of the plastic components. These cutting methods ensure accuracy and consistency in the final product while minimising material waste.

4. Forming and Moulding

Forming and moulding are essential processes in plastic fabrication, allowing for the creation of complex shapes and structures. Techniques such as thermoforming, injection molding, and vacuum forming are commonly used to heat and shape the plastic materials into the desired forms. These methods offer flexibility and efficiency in production, enabling manufacturers to produce large quantities of identical parts with high precision.

5. Joining and Assembly

Once the individual components are formed and molded, they are assembled and joined together to create the final product. Joining techniques such as solvent bonding, welding, and mechanical fastening are used to securely connect the plastic parts. Skilled technicians carefully assemble the components according to the design specifications, ensuring structural integrity and functionality.

6. Finishing and Surface Treatment

The finishing touches are applied to the fabricated plastic products to enhance their appearance and functionality. Surface treatments such as polishing, sanding, and coating are used to achieve smooth and uniform surfaces, remove imperfections, and add protective layers. Decorative finishes such as painting, printing, and engraving can also be applied to customise the appearance of the products according to the client's specifications.

7. Quality Control and Testing

Throughout the fabrication process, quality control measures are implemented to ensure the integrity and performance of the final product. Rigorous testing procedures, including dimensional checks, strength tests, and durability assessments, are conducted to verify compliance with industry standards and customer requirements. Any deviations or defects are promptly identified and addressed to maintain the highest level of quality.

8. Packaging and Shipping

Once the plastic products have passed quality control inspections, they are carefully packaged and prepared for shipping to their destination. Proper packaging protects the products from damage during transit and ensures they arrive safely at the end user. Efficient logistics and supply chain management play a crucial role in delivering the fabricated products to customers in a timely manner. In conclusion, the process of plastic fabrication is a complex and intricate journey that involves careful planning, precise execution, and attention to detail at every stage. From design and material selection to cutting, shaping, forming, and assembly, each step contributes to the creation of high-quality plastic products used in diverse industries around the world. By revealing the behind-the-scenes process of plastic fabrication, we gain a deeper appreciation for the ingenuity and craftsmanship involved in bringing everyday products to life.