In the dynamic landscape of commercial design, the concept of bespoke fabrication emerges as a beacon of innovation and customization. As businesses strive to differentiate themselves and create unique brand identities, the demand for tailor-made solutions in commercial spaces has surged. From retail establishments to corporate offices, bespoke fabrication offers a versatile toolkit for architects, designers, and business owners alike to craft spaces that resonate with their vision and purpose.

The Essence of Bespoke Fabrication

Bespoke fabrication transcends the limitations of off-the-shelf solutions, offering a bespoke approach tailored to the specific needs and aspirations of each project. At its core, bespoke fabrication embodies the art of customisation, where form meets function in a seamless fusion of design and craftsmanship.

In the realm of commercial spaces, the requirements are as diverse as the businesses they house. Whether it’s a flagship store seeking to create an immersive brand experience or a collaborative workspace aiming to foster creativity and productivity, bespoke fabrication provides the flexibility to realise ambitious design concepts while addressing practical considerations.

Tailored Solutions, Endless Possibilities

One of the key advantages of bespoke fabrication lies in its ability to accommodate a wide array of materials, techniques, and design preferences. From wood and metal to glass and composite materials, the palette of possibilities is virtually limitless. This versatility enables designers to experiment with textures, finishes, and structural elements, thereby creating spaces that are both visually striking and functionally robust.

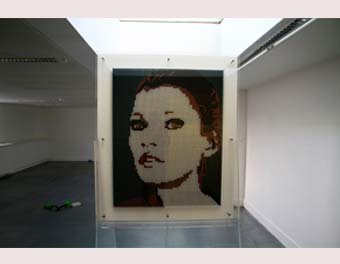

Moreover, bespoke fabrication allows for the integration of advanced technologies such as CNC machining, laser cutting, and 3D printing, enabling the realisation of intricate patterns, complex geometries, and interactive installations. Whether it’s a custom-built display unit, a sculptural centrepiece, or a kinetic façade, the only limit is the imagination.

Elevating the customer experience

In today’s competitive business landscape, the customer experience reigns supreme. From the moment a patron sets foot inside a retail store or steps into a hotel lobby, every interaction shapes their perception of the brand. Bespoke fabrication offers a powerful means to curate memorable experiences that resonate with customers on a visceral level.

By infusing elements of craftsmanship and artistry into the built environment, bespoke fabrication elevates the customer experience from mundane to extraordinary. From handcrafted fixtures and bespoke furniture to immersive multimedia installations, every detail serves as a testament to the brand’s commitment to excellence and innovation.

The Future of Commercial Design

As we look to the future, the role of bespoke fabrication in commercial design is poised to expand even further. With advancements in digital fabrication, sustainable materials, and parametric design, the possibilities for innovation are boundless. From sustainable architectural solutions to interactive retail environments, bespoke fabrication will continue to shape the way we experience and interact with commercial spaces. In conclusion, bespoke fabrication represents a paradigm shift in the way we conceive, design, and inhabit commercial spaces. By offering tailor-made solutions that marry form and function, bespoke fabrication empowers businesses to create environments that inspire, engage, and delight. As the boundaries of design continue to blur, bespoke fabrication stands as a testament to the enduring power of creativity and craftsmanship in shaping the world around us.