Coloured acrylic is a versatile and stylish material that has found its way into a variety of applications, from interior design to retail displays. Whether you are looking to make a bold statement or add subtle accents, coloured acrylic offers a range of possibilities to suit your needs. In this guide, we will explore the factors to consider when choosing the right coloured acrylic for your project.

Understanding coloured acrylic

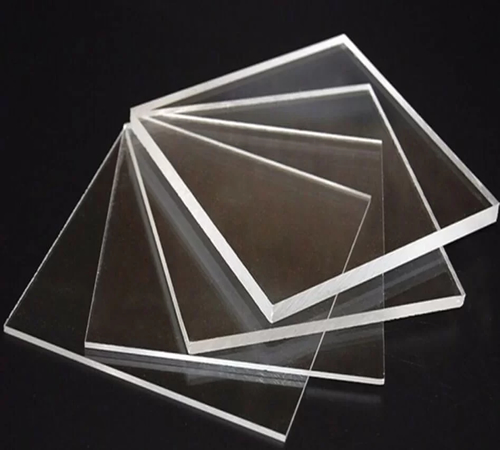

Acrylic is a type of thermoplastic that is prized for its durability, light weight, and optical clarity. Coloured acrylic takes these advantages a step further by incorporating vibrant or muted hues into the material. It is available in solid, transparent, translucent, and even fluorescent finishes, allowing for a wide variety of creative applications.

Key benefits of coloured acrylic

- Durability: Coloured acrylic is highly resistant to impact and weathering, making it suitable for both indoor and outdoor use.

- Customisation: With an extensive range of colours and finishes available, you can easily tailor coloured acrylic to fit your specific aesthetic or branding needs.

- Lightweight: Compared to glass, acrylic is significantly lighter, making it easier to handle and install.

- UV resistance: Many coloured acrylic sheets come with built-in UV resistance, ensuring that the colour remains vibrant over time, even when exposed to sunlight.

Applications of coloured acrylic

Coloured acrylic is used across various industries due to its versatility and visual appeal. Common applications include:

- Retail displays: Perfect for signage, point-of-sale displays, and shelving, coloured acrylic can help draw attention to products.

- Interior design: From furniture to decorative panels, coloured acrylic adds a modern touch to any space.

- Lighting: Translucent and fluorescent acrylic sheets are ideal for creating diffused lighting effects or bold light features.

- Art and crafts: Artists and designers often use coloured acrylic to produce striking sculptures or creative installations.

Factors to consider when choosing coloured acrylic

When selecting coloured acrylic for your project, keep the following in mind:

- Colour and finish: Decide whether you need a solid, transparent, or translucent colour. Consider the effect you want to achieve and how the colour interacts with lighting in your space.

- Thickness: The thickness of the acrylic sheet can affect its durability and appearance. Thicker sheets are sturdier and create a more prominent visual impact.

- Environment: If your project involves outdoor use, ensure the acrylic is UV-resistant and weatherproof.

- Cutting and shaping: Acrylic can be cut and shaped to your specifications, so it’s important to choose a supplier that offers customisation options.

Maintaining coloured acrylic

Proper maintenance is essential to preserve the look and longevity of your coloured acrylic. Here are some tips:

- Cleaning: Use a soft, damp cloth and a mild detergent to clean the surface. Avoid abrasive cleaners that could scratch the material.

- Polishing: If the surface becomes dull or scratched, an acrylic polish can help restore its clarity and shine.

- Handling: Handle acrylic sheets with care to prevent cracks or chips, especially along the edges.

Conclusion

Choosing the right coloured acrylic can transform your project, adding both functionality and aesthetic appeal. By considering factors such as colour, finish, and application, you can select an acrylic sheet that perfectly aligns with your vision. Whether you are designing a retail display or enhancing your home decor, coloured acrylic offers endless possibilities for creativity and innovation.