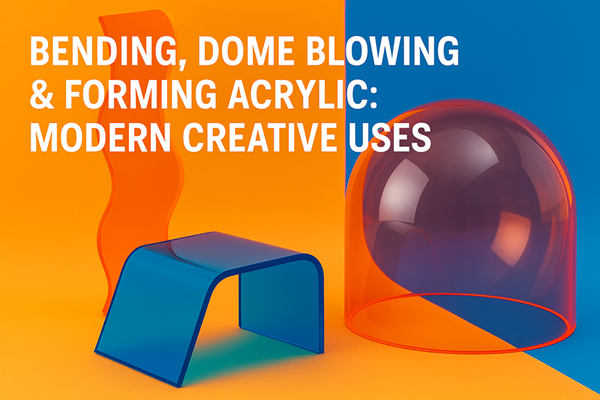

When most people think of acrylic, they imagine flat sheets for signage or display cases. But in skilled hands, acrylic becomes so much more, a material you can bend, stretch, blow, and shape into forms that defy expectations.

Acrylic fabrication has evolved far beyond simple heat forming. With modern equipment and a creative mindset, bending, dome blowing, and complex forming techniques open the door to wildly inventive, and surprisingly practical, applications. Here’s what that really looks like.

Acrylic bending: When function meets flair

Heat bending is the foundation of acrylic fabrication. It’s not just about angles or right-angled displays, think fluid architectural curves, ergonomic furniture, or sculptural lighting designs.

Acrylic can be line-bent for crisp edges or strip-heated to achieve smooth, rolling arcs. Precision jigs allow for repeatable results, making it perfect for:

- Retail displays that demand sleek, modern shapes

- Protective barriers with curved profiles for improved sightlines

- Furniture design, where form and transparency merge

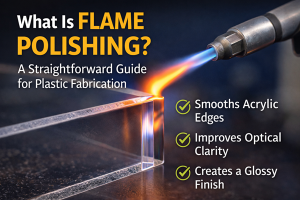

When bent correctly, the finish stays optically clear, no bubbles, burns, or cloudiness. The trick lies in precise temperature control and slow cooling to prevent stress cracking later.

Dome blowing: Acrylic’s answer to glass innovation

Dome blowing, or bubble forming, is where acrylic truly starts to outshine glass. By heating sheets evenly and using air pressure, you can form perfect domes, spheres, and compound curves with exceptional optical clarity and impact resistance.

This technique is ideal for:

- Aquarium viewing panels and zoo enclosures: Strong, distortion-free, and lighter than glass

- Architectural skylights and roof domes: Custom sizes, seamless appearance, and UV-stable clarity

- Lighting diffusers and art installations: A sculptor’s dream for capturing and playing with light

The creative side? Artists and designers have used blown acrylic to make futuristic helmets, automotive concepts, and even interactive public sculptures. The key benefit: you can achieve massive clarity without the weight or fragility of glass.

Forming acrylic: Sculpting with science

Beyond bending and blowing lies thermoforming, where acrylic sheets are heated and pulled over moulds or into vacuum formers. This process gives complete control over complex 3D shapes.

Modern forming allows for:

- Curved signage and branded features with integrated lighting

- Medical and laboratory equipment covers with exact tolerances

- Automotive and marine components, shaped for aerodynamics and aesthetics

- Public art and installations, blending precision with expressive design

Using CNC-cut moulds or 3D-printed forms, even intricate geometries can be replicated consistently. Once cooled, the formed acrylic maintains rigidity, clarity, and impressive resistance to impact and weathering.

Why acrylic wins over glass and metal

Acrylic fabrication isn’t just creative; it’s practical. Compared with glass or metal:

- It’s half the weight of glass but up to 17 times stronger

- It doesn’t shatter, making it safer for public or outdoor use

- It can be laser-cut, bonded, bent, blown, and polished with precision

- It comes in clear, tinted, mirrored, and frosted finishes for design flexibility

Combine that with sustainability advances, including recyclable acrylics and offcut reuse, and it’s no wonder architects, artists, and engineers are pushing its limits.

The future of acrylic design: Bold, curved, and bespoke

From immersive museum domes to custom motorcycle windshields, the possibilities with advanced acrylic fabrication are virtually endless. What used to be a “sheet material” is now a creative medium, one that bridges engineering and art. If you’ve only seen flat panels and box displays, it’s time to rethink what acrylic can do. Whether you’re an architect, designer, or manufacturer, bending, dome blowing, and forming can turn your ideas into something truly striking, durable, precise, and brilliantly clear.