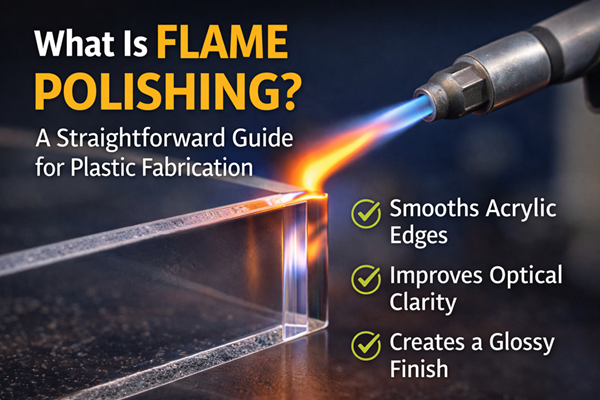

If you’ve ever seen a piece of acrylic with perfectly clear, glass-like edges, there’s a good chance it’s been flame polished. Flame polishing is a finishing method used mainly on plastics such as acrylic to improve edge clarity, smoothness, and overall appearance. It’s widely used in fabrication, signage, retail displays, and high-end plastic components where visual quality matters.

This guide explains what flame polishing is, how it works, when to use it, and what you need to know before choosing it for your project.

What is flame polishing?

Flame polishing is the process of passing a controlled flame over the cut edge of a thermoplastic material, typically acrylic (also known as Perspex or PMMA). The heat from the flame briefly melts the surface of the plastic, allowing it to reflow and smooth itself out.

As the plastic cools almost instantly, it solidifies into a clear, glossy finish.

The result is:

- Smooth edges

- Improved optical clarity

- A professional, high-end appearance

- Removal of minor saw marks and surface imperfections

Unlike sanding or mechanical polishing, flame polishing relies on heat rather than abrasion.

Why flame polishing is used

When acrylic is cut with a saw, CNC router, or laser, the edges often appear frosted, dull, or slightly rough. Even precise cuts leave microscopic imperfections that scatter light and reduce clarity.

Flame polishing fixes this by restoring transparency and smoothness.

It’s commonly used for:

- Retail display cases

- Acrylic furniture

- Point-of-sale displays

- Protective screens

- Signage

- Museum and exhibition pieces

- Aquariums and enclosures

In any environment where appearance matters, flame polishing makes a visible difference.

How flame polishing works

The principle is simple, but execution requires skill and control.

A trained operator uses a gas torch, usually fuelled by hydrogen, propane, or oxyhydrogen, and moves the flame quickly and evenly across the acrylic edge.

The heat briefly melts only the outermost surface layer. Surface tension naturally smooths out the microscopic peaks and valleys. The plastic then cools within seconds, leaving a clear, polished edge.

The key factors are:

- Flame temperature

- Speed of movement

- Distance from the surface

- Material thickness

- Material quality

Too much heat causes bubbling, distortion, or stress damage. Too little heat achieves nothing.

This is why proper flame polishing techniques matter, it’s not something you can fake with guesswork.

Flame polishing vs other polishing methods

Flame polishing is just one of several finishing options. Each has its place.

Flame polishing

Best for: Clear acrylic, cosmetic finishes, straight edges

Result: High gloss, crystal-clear finish

Speed: Fast

Cost: Efficient for production work

Diamond polishing

Best for: Thick acrylic, structural applications

Result: Highest precision and clarity

Speed: Slower

Cost: Higher

Mechanical polishing (sanding and buffing)

Best for: Small parts, manual finishing

Result: Good finish but more labour-intensive

Speed: Slow

Cost: Labour-dependent

Flame polishing is often the most cost-effective solution when appearance is the priority and edges are accessible.

Advantages of flame polishing

There’s a reason it’s widely used in acrylic fabrication.

Excellent clarity

It restores near-original transparency to cut edges.

Fast process

It’s significantly quicker than manual polishing methods.

Cost-effective

Especially suitable for batch production and larger pieces.

Professional appearance

Creates clean, glossy edges that improve perceived quality.

Limitations and Risks

Flame polishing isn’t perfect in every situation.

Can introduce internal stress

Improper technique can create stress points that weaken the material over time.

Not ideal for load-bearing parts

If the acrylic will be structurally stressed, diamond polishing may be safer.

Requires skilled handling

Inexperienced operators can cause:

- Edge distortion

- Bubbles

- Surface crazing

- Permanent damage

Not suitable for all plastics

It works best on acrylic. Other plastics like polycarbonate do not respond the same way.

Where you’ll commonly see flame polished acrylic

You’ve probably seen flame polished acrylic without realising it.

Examples include:

- Shop display stands

- Cosmetic display units

- Protective barriers

- High-end signage

- Furniture components

- Award plaques

- Exhibition panels

That smooth, glass-like edge is usually the result of flame polishing.

Is flame polishing the right choice for your project?

It depends on your priorities.

Flame polishing is ideal if you want:

- Maximum visual clarity

- Smooth, glossy edges

- Fast turnaround

- Cost-efficient finishing

It may not be the best option if:

- The part is structural or load-bearing

- Precision tolerances are critical

- Internal stress must be minimised

In those cases, diamond polishing is often preferred.

Final thoughts

Flame polishing is one of the most effective ways to improve the appearance of acrylic. It transforms rough, dull edges into smooth, crystal-clear surfaces that look professional and high-quality.

When done correctly, it’s fast, efficient, and delivers excellent results. However, it requires proper equipment and skilled handling to avoid damaging the material.

If you work with acrylic regularly, whether in signage, fabrication, retail displays, or manufacturing, understanding flame polishing helps you choose the right finish for both performance and presentation.