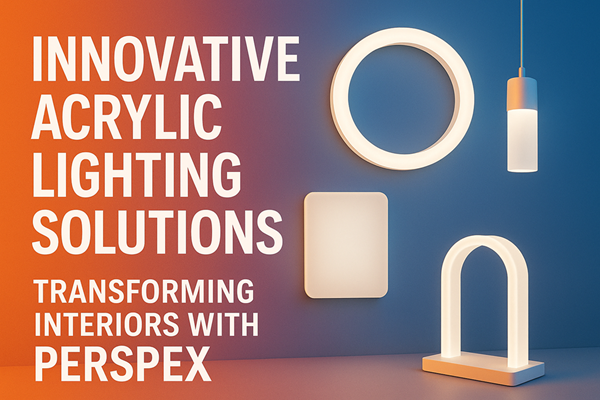

Acrylic lighting has become a leading choice for modern interior design because it delivers clean lines, soft diffusion, and a premium look without the weight or fragility of glass. Perspex is a reliable acrylic material for lighting because of its clarity, durability, and flexibility. This guide explains how Perspex lighting works, where it delivers the most impact, and how Denny Plastics creates high quality bespoke lighting components for commercial and residential spaces.

Why Perspex is ideal for lighting systems

Perspex is a cast acrylic known for its excellent light transmission, strength, and ease of fabrication. It can be laser cut, CNC machined, thermoformed, bonded, and polished, which makes it suitable for detailed lighting projects that require precision.

Key advantages:

- High clarity and strong light transmission

- Lightweight and safer than glass

- Shatter resistant and reliable in public spaces

- Available in clear, frosted, tinted, and LED-diffused grades

- Can be shaped into flat panels, curves, tubes, and custom forms

Because Perspex is so versatile, it allows lighting designers to produce bespoke features that combine aesthetics with function.

How acrylic lighting improves interior spaces

Acrylic lighting enhances both the style and performance of a room. It softens harsh LED points, creates smooth diffusion, and helps light become part of the design rather than just an overhead source.

Main benefits include:

- Even, controlled diffusion

- Reduced glare and better visual comfort

- Modern, minimal aesthetic

- Compatibility with LED systems

- Lightweight solutions for walls, ceilings, shelves, and suspended features

These benefits make Perspex lighting a strong choice for anyone wanting a clean, contemporary finish.

Real project example: Hotel feature wall installation

To strengthen practical understanding, here is a real-world style example based on typical client requirements.

A hotel refurbishment project required a continuous illuminated feature wall in the reception area. The design team specified 10mm frosted Perspex shaped into curved panels to achieve a seamless glow with no visible LED hotspots. Denny Plastics fabricated the panels using CNC machining, thermoforming, and UV bonding to create a clean, joint-free finish. The result was a durable, lightweight lighting feature that delivered consistent brightness throughout the entire wall.

This type of project demonstrates how Perspex can handle aesthetic demands, structural requirements, and long term durability in a busy commercial space.

Where Perspex lighting creates the most impact

Retail and commercial spaces

Retailers use acrylic lighting to highlight products and reinforce brand identity. Popular applications include:

- Edge-lit display shelves

- Backlit counters and wall panels

- Illuminated logos and signage

- Suspended geometric lighting features

Acrylic offers strong visual impact while remaining cost effective and durable.

Hospitality and leisure venues

Restaurants, hotels, and bars use Perspex lighting to shape ambience and elevate their interiors.

Examples:

- Frosted bar fronts with LED diffusion

- Decorative panels with backlighting

- Large formed acrylic pendants

- Illuminated reception features

Acrylic’s strength makes it ideal for long opening hours and high footfall.

Workspaces and modern offices

Offices rely on Perspex lighting for clean, minimal interiors that support comfort and productivity.

Common uses:

- Diffused ceiling panels

- Edge-lit partitions

- Integrated lighting in desks and cabinets

- Branded illuminated wall features

Acrylic helps soften LED glare in open plan environments.

Residential environments

Homeowners use acrylic lighting to add modern touches to living rooms, kitchens, and bathrooms.

Uses include:

- Backlit splashbacks

- Floating shelves with edge lighting

- Under stair lighting

- Backlit mirrors

These features provide subtle ambience while remaining energy efficient.

Main types of Perspex lighting

Edge-lit acrylic

LEDs are fitted along the panel edges. Engraved or patterned areas glow when lit. Ideal for signage, floating shelves, and decorative features.

Backlit acrylic

LEDs sit behind a diffused Perspex panel to create a smooth, even glow. Used in counters, feature walls, and ceiling panels.

Acrylic light boxes

Framed units for retail, hospitality, and exhibitions where bright, even visuals are required.

3D formed Perspex lighting

Curved, domed, or sculptural lighting elements made through thermoforming. It is suitable for dramatic centrepiece installations.

LED-diffused Perspex grades

Special acrylic designed to hide LED sources and provide uniform lighting.

Why Perspex often outperforms glass for lighting

- Half the weight, easier to install

- Safer and more impact resistant

- More flexibility for custom shapes

- Better LED diffusion and light control

- Lower maintenance over time

These advantages make acrylic the preferred choice for both small projects and large interior lighting systems.

How Denny Plastics fabricates high quality acrylic lighting

Denny Plastics produces bespoke lighting components using:

Their team works on projects ranging from retail rollouts to one-off architectural lighting features, ensuring accuracy, durability, and strong visual results.

FAQ

How long does Perspex lighting last?

Acrylic lighting can last many years. Perspex is resistant to cracking, UV degradation, and general wear, making it reliable for both residential and commercial environments.

Can Perspex lighting be used in warm or humid areas?

Yes. As long as you use the correct grade and installation method, Perspex performs well in kitchens, bathrooms, and hospitality spaces.

Final thoughts

Perspex lighting offers clarity, durability, and strong design flexibility. It works across retail, hospitality, offices, and homes, providing modern lighting solutions that stand out visually and perform reliably. With expert fabrication from Denny Plastics, acrylic lighting can transform any interior into a cleaner, brighter, and more contemporary space.